To shape the future, cutting edge materials need not be as fascinating as topological encasings and metamaterials. Specialists are exploring the capability of nanocellulose—a nanostructured type of cellulose that can be gotten from the modest wood chip—for applications going from microfluidic gadgets to battery-powered batteries. A group drove by Liangbing Hu at the University of Maryland in College Park detailed at the 2019 Fall Meeting of the Material Research Society in Boston that a material that joins nanocellulose with graphite has mechanical properties that outperform those of steels and of other set up basic materials. The recyclable composite could offer an earth benevolent option for building lightweight vehicles, air ship, and body armor.

Hu introduced a diagram of his journey for supplanting conventional materials with feasible ones dependent on wood nanocellulose. The cellulose filaments that make up nanocellulose have measurements of somewhere in the range of 5 and 20 nm and lengths of a few micrometers. They are ordinarily arranged from wood mash utilizing mechanical strategies that tear the mash’s wood filaments into nanoscale bristles.

“Wood and materials derived from [wood] have a lot to offer,” Hu says, noticing that wood-based materials are recyclable, biocompatible, and biodegradable. “These are fantastic properties, but to make these materials successful, we need to show that their performance is superior to that of traditional materials,” he includes.

Utilizing nanocellulose, Hu’s group has as of late exhibited a straightforward wood that could sub for glass and a high-quality nanopaper that could supplant plastic. In the new work, they followed imitating the basic properties of steel.

Structural materials owe their solidarity to the nearness of solid, essential synthetic bonds between their particles: metallic bonds in metals and metal composites, carbon-carbon covalent bonds in carbon strands, and ionic bonds in earthenware production. The quality of these bonds, notwithstanding, is both a gift and a revile. To control, make, and reuse these materials, these bonds must be broken and changed, which requires high temperatures and devours a lot of energy, prompting a considerable expense and a strong natural footprint.

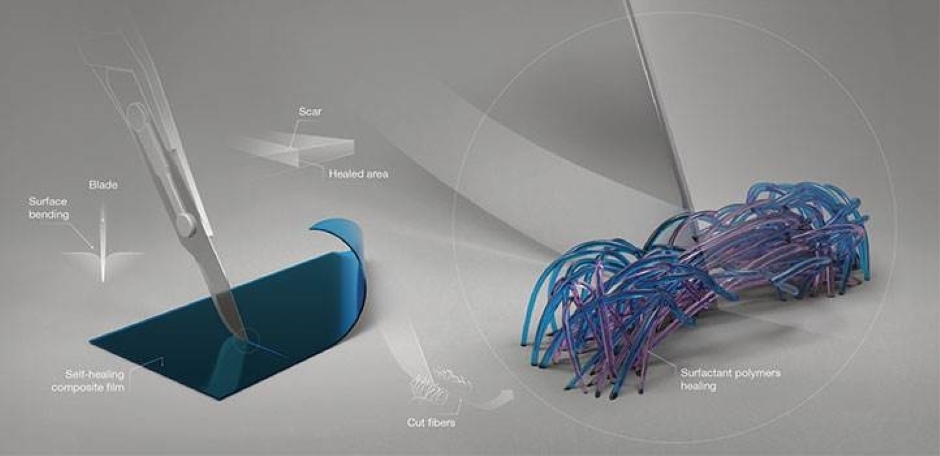

The material structure methodology of Hu and his associates use auxiliary substance bonds, for example, the hydrogen bonds that are bottomless in natural materials like nanocellulose. While the energy expected to represent the deciding moment an individual hydrogen bond is a lot littler than that of an essential compound bond, systems of these bonds can make a material amazingly solid, something the group knew from their past work on cellulose nanopaper. Their nanopaper is requests of extent more grounded and harder than customary paper, on account of the plentiful number of optional hydrogen bonds that structure between the paper’s cellulose nanofibers, and gratitude to the straightforwardness and speed with which these bonds change when broken.

For the steel-like material, the group tackled these bonds to “stick” the cellulose to graphite, which is hard yet too weak to ever be utilized in load-bearing structures. To create a graphite-nanocellulose composite, they arranged a profoundly focused slurry of water, graphite chips, and nanocellulose at room temperature. They at that point cast-printed this blend into meter-huge, 20-μm thick layers. The layers were adaptable—they could be twisted to a range of 2 mm without breaking—and different layers could be hot squeezed into thicker sheets.

Mechanical estimations show that the material is incredibly strong. The printed sheets are more grounded than treated steel and multiple times as light. The material’s particular quality (characterized as the quality isolated by the material’s thickness) is higher than that of materials utilized in basic applications, similar to steels, aluminum composites, and titanium compounds.

The analysts described the composite to uncover the minute structure behind its mechanical properties, utilizing a blend of nuclear power microscopy, transmission electron microscopy, and atomic elements reproductions. Their investigation proposes that a large number of cellulose nanofibers join to every one of the graphite chips—whose sizes are in the several micrometers extend—through hydrogen holding. The strands likewise interface distinctive graphite pieces. “It’s like a brick wall, where the graphite flakes are the bricks, and the cellulose nanofibers are the mortar that glues the bricks together,” says Yubing Zhou, the postdoctoral individual in Hu’s group who drove the study.

Hu cites a few ecological preferences of the composite. Its manufacture procedure doesn’t include the utilization of any harsh chemicals, and the composite can be effectively reused—a basic cutting and blending procedure can transform the material go into the first slurry. “The material’s properties are exceptional. Now we just need to find cheaper ways to make it and scale up the production process,” says Hu.

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Graph Daily journalist was involved in the writing and production of this article.