The prototype thermoelectric material has been created by the KAUST group in Saudi Arabia with three organic compounds.

Sensors worn on the skin or as implants can monitor significant markers of human health, including heart rate, blood pressure, brain activity, muscle motion, calories burned and the release of specific chemicals. A definitive objective is self-powered wearable technologies, however, these will require a reliable and durable source of electricity.

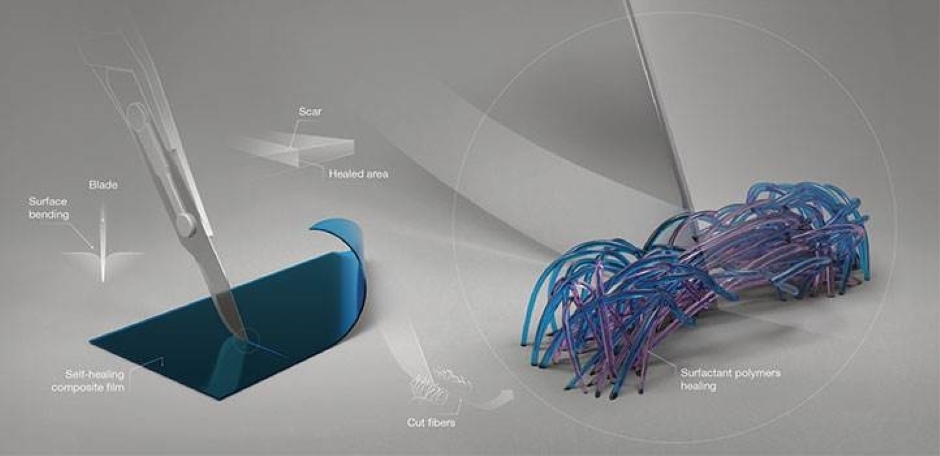

Thermoelectric materials, which use temperature gradients to create electricity, can power wearable technologies utilizing body heat, eliminating the requirement for batteries. Current materials, in any case, lack the adaptability, quality, and flexibility to abstain from being harmed.

A group led by Derya Baran and Seyoung Kee at KAUST have mixed the highly conductive thermoelectric polymer PETOT:PSS (poly(3,4-ethylene dioxythiophene) doped with polystyrene sulfonate), with dimethyl sulfoxide, an organic compound that lifts the performance of PETOT:PSS, and Triton X-100, a sticky, gel-like specialist that supports hydrogen bonding with PETOT:PSS. The exploration is depicted in Advanced Functional Materials.

“This final ingredient was essential for providing the stretchy and self-healing properties we needed,” Kee said in a statement.

The scientists used a 3D printer to store their mixture and afterward tested the thermoelectric performance of these movies under duress. To begin with, they found that the temperature contrast between the two sides of the film created the most extreme power output of 12.2nW.

The group is then said to have tested the self-healing behavior of the movies by cutting them in half while they powered an LED light. “Amazingly, the light did not go out during or after cutting,” said Kee. “I repeated the cut ten times, but it continued to self-heal in less than one second and retained 85 percent of its power output.” Additionally, when they extended the film to around a third longer than its original size, despite everything it gave a steady power supply.

“Wearable electronics are under continuous strain, and their power supply is prone to breaking,” said Kee. “Our material can provide constant and reliable power because it can deform, stretch, and most importantly, heal itself…Next, we must find materials with even better thermoelectric properties so that we can generate greater power shortly.”

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No Graph Daily journalist was involved in the writing and production of this article.